Products

Energy solutions that Awaken Industrial Vitality

KRF

DRYFOG Humidification Principle and Post-Improvement Effects

01

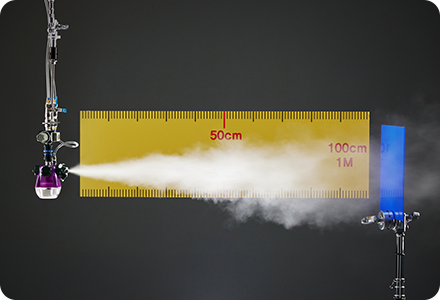

Sprays water droplets through ultra-fine nozzles using AIR, immediately vaporizing them to control indoor humid air.

02

Spray particles are 4.5㎛~9㎛ and immediately vaporize into humid air, eliminating condensation on floors.

03

When spray direction is obstructed, ANGLE-ADAPTOR (360º direction conversion angle adjuster) is installed to resolve the issue.

04

Powerful spray force like a waterfall, generates negative ions through LENARD effect to remove static electricity, fine dust, etc., improving indoor air quality.

05

Sprays supply water through RO produced by membrane filter, resolving whitening phenomenon and NOZZLE clogging issues.

DRY FOG Humidification Features

Clean Humidification Effect - Lenard effect

(Waterfall effect)

- No whitening phenomenon when vaporizing pure water produced by membrane filter through Dryfog spraying

- Sprays by colliding water droplets like a waterfall, maintaining clean indoor air through Lenard effect (negative ion generation)

No Condensation Phenomenon

- Prevents condensation on objects by adopting ultra-fine nozzles and installing 360º convertible direction angle adjuster (Option) to prevent supersaturation, while introducing automatic control system through humidity sensors.

Static Electricity and Fine Dust Prevention

- Generates negative ions through Dryfog spray Lenard effect, removing static electricity and fine dust.

Static Electricity and Fine Dust Prevention

- Dryfog sprayer Head is semi-permanently durable and easy to control with Siphon method that only supplies water and air

- Not a water boiling method, but provides pure water through RO MEMBRANE FILTER method

Static Electricity and Fine Dust Prevention

- Utilizes cooling humidification effects on equipment and lines with indoor heat generation to reduce refrigerator usage (electric energy savings)

Reduces fossil fuel use and prevents global warming through LNG and Steam energy savings

- Humidification method that complies with global climate environmental policies by reducing CO2 emissions through greenhouse gas reduction.

Patent Strategy Institute Import Substitute Development Product

- Conducted DRYFOG sprayer development project as Patent Strategy Institute import substitute task

- Applied for and registered 1 patent and 3 designs

- Developed and launched DRYFOG new product – KRF21A (ultra-fine special nozzle)

- Launched DRYFOG Adapter product – Angle 360º direction conversion

- Developed and launched IOT controller product – MODBUS RTU RS485 communication compatible (HMI, SCADA compatible)

| Category | Features and Performance |

|---|---|

| Nozzle Method | Siphon type, External collision type (two-fluid) |

| AIR Consumption (0.3Mpa) | 4 NOZZLE-140ℓ (ℓ/min) |

| WATER Spray Volume (0.3Mpa) | 4 NOZZLE-11.6ℓ (ℓ/hr) |

| Average Particle Size | 4.5~9μm |

Features

Specifications

- Average particle size: 4.5~9㎛

- Spray volume: 2.9L/h per nozzle at air pressure 0.3Mpa

- Ultra-compact tank: Height 110mm, body diameter 90mm (nozzle span 130mm)

- Mass approximately 350g (with 4 NOZZLES attached, when full)

Materials

- Humidifier body: PC&PE and STS316

- Nozzle: POM&PC

- O-ring: SILICON&POM

- Packing: SILICON

Electronics, Semiconductor, Automotive, Aviation, Chemical, Painting, Printing, Injection Molding

SMT, SMD, FPCB, PCB, Clean Room, Plastic, Steel Mill

Tobacco, Paper, Textile, Dust Control, Deodorization, Sanitization, Sterilization, Disinfection

ANGLE ADAPTOR

KRF Angle Adaptor

An Adaptor that allows free spraying by adjusting 360° spray angle from conventional Nozzles that spray in 4 straight directions

An Adaptor that can be used for concentrated spraying in the same direction as the Nozzle, or freely converted and used wherever needed An Adaptor that can freely humidify 1~4 directions according to required humidification volume