Products

Energy solutions that Awaken Industrial Vitality

Pure Water System (R/O, UPW)

Concept of Purity (Pure Water)

Water without impurities, where the degree of purity is determined by conductivity and resistivity.

Degree of Purity

- Types of supply water to pure water systems: 1. Tap water 2. Industrial water 3. Groundwater, etc.

- Tap water: approximately 120~150us/cm, Industrial water: 150us~250us

- Groundwater, etc.: approximately 300 ~ 1000us/cm (water softener required)

- Types of production water from pure water systems: General humidification uses primary pure water, with additional filter configurations according to purpose.

- Type III (Primary pure water = RO water): 5 ~ 35 us/cm

Uses: Cleaning water, humidification, ultra-pure water supply...

- Type II (Secondary water): 1 ~ 10 MΩ-cm

Uses: Beverage & cosmetic manufacturing water, culture medium preparation, hospital biochemistry and immunology equipment, etc...

- Type I (Tertiary ultra-pure water = UP water): 18.2 MΩ-cm

Uses: Beverage & cosmetic manufacturing water, culture medium preparation, hospital biochemistry and immunology equipment, etc...

Applications

-

Semiconductor Industry - Semiconductor wafer (Micro-Electronic Wafer) cleaning, etc.

-

Electrical, Electronics, Automotive, PCB, FPCB, PSR, SMT, SMD process

humidification -

Chemical Industry (Chemical Industries) - Chemical reagent dilution and container cleaning, etc. Prevention of product congelation or deterioration due to oxidation reactions

-

Pharmaceutical Industry and Medical Field (Pharmacy Manufactures & Medical Institutions) - Manufacturing of Ringer's solution and other injection distilled solutions, cleaning during medical device manufacturing processes, or purification of contaminated blood by artificial kidneys, prevention of bacterial infections and side effects by pyrogens, experimental water, etc.

-

Paint Industry (Paint Industries) - Water-based paint manufacturing (Prevention of deterioration and congelation phenomena by oxidation substances)

-

Plating Industry (Plating industries) - Deionized water for electroplating. Prevention of deposition rate reduction and spotted phenomena in plating films

-

Food Processing (Food Processing) - Prevention of product spoilage and deterioration by oxidizing substances and microorganisms

Prevention of pigment congelation phenomena in soft drinks. -

Used for cosmetic water and chiller cooling water

-

Used for cosmetic water and chiller cooling water

What are Pure Water and Ultra-Pure Water?

- What is Ultra-Pure Water?

-

Water that suppresses electrical conductivity, solid particle count, viable bacteria count, organic matter, etc. to extremely low values.

In ultra-pure water, there are limits such as particles with diameter 0.1μm or less being 20/cm or less, viable bacteria being 1 per 100cm, etc., and theoretically it is water with resistivity of 18.2 MΩ/cm.

Ultra-pure water is made by combining distillation, ion exchange, reverse osmosis, etc., and is widely used in various industrial processes such as semiconductor or electronic device manufacturing, pharmaceutical manufacturing, food manufacturing, thermal or nuclear power plants, cosmetics, battery charging, etc.

- Utilization of Ultra-Pure Water

-

With rapid industrial growth and improved living standards, the demand for domestic and industrial water is increasing, and it is currently widely used in industrial sites and laboratories.

The raw water used in Korea is mostly river water, lake water, groundwater, and tap water, and these raw waters contain large amounts of impurities, which can cause various problems if used directly in various facilities.

Therefore, using treatment devices (called RO pure water or DI Water) that can remove impurities

Impurities that can come from raw water include solids, dissolved solids, organic matter, inorganic matter, and various ionic components (lime, calcium, magnesium, iron), etc. When water containing such impurities is used, it can cause scale in various facilities, interfering with heat conduction, clogging pipes and obstructing flow, and causing corrosion.

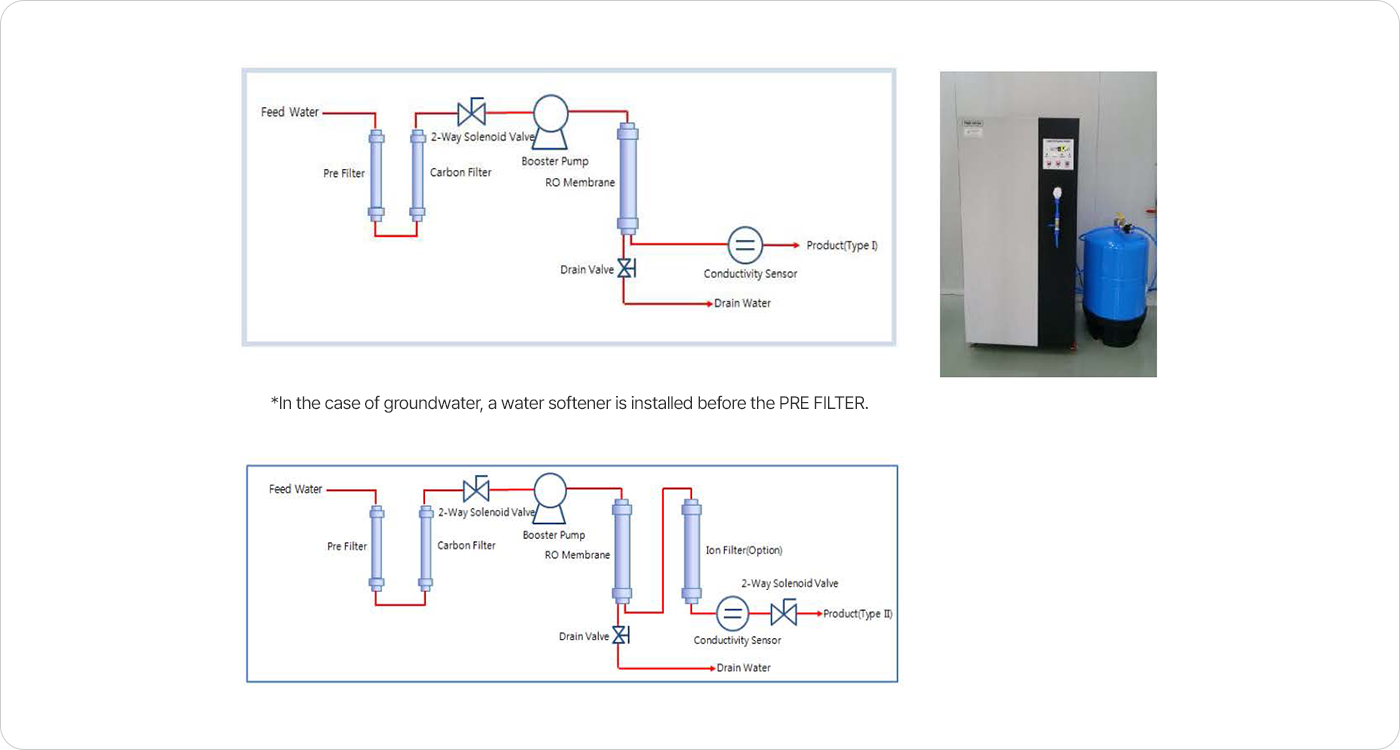

Description of RO/UPW Pure/Ultra-Pure Water Manufacturing System (System Diagram)

- RO3 Pure Water System (Basic 3-stage - Pre Filter, Carbon Filter, RO Membrane Filter)

- For ultra-pure water use, ion exchange resin filters are installed in addition to RO 3-stage filters (Pre, Carbon, Membrane).

- ION Filter, FINAL Filter, UV LAMP (when using ultra-pure water)

- Purpose: Prevention of whitening phenomenon, removal of lime, calcium, magnesium, iron, bacteria removal, nozzle clogging prevention

Product Images